Grinding in Mineral Processing: Principles, Types, and Circuits

Introduction

Grinding is the second step of mineral processing and the last stage of the comminution process. The product from a crushing unit is fed to a mill in order to decrease the particle size (sometimes even to 10 microns) for subsequent processing. The reduction ratio is usually large (8 to 25:1 sometimes 500:1).

The purpose of grinding differs with the material being ground. For example in a processing plant, the primary purpose is to liberate individual minerals trapped in ores for a subsequent enrichment. In some non-metallic beneficiation, grinding is practiced to satisfy market requirements. In hydro-metallurgical work, exposure of valuable mineral to the leach solution is the main purpose of grinding.

Principles of Grinding

Grinding is performed in a rotating cylindrical steel vessel which contains crushed ore with a grinding medium free to move inside the mill, lifted by the rotation of the drum, to break the ore to produce a specified product. The grinding medium can be the ore itself, natural or manufactured non-metallic media or manufactured steel e.g. steel rods, steel or iron balls.

Grinding within a mill is influenced by the size, quantity, the type of motion and the spaces between the individual pieces of the medium in the mill. Grinding is a more random process and is subjected to the laws of probability. The degree of grinding of an ore particle depends on the probability of the ore entering a zone between the medium shapes.

Figure 1: Mechanisms of breakage – (a) impact or compression, (b) chipping, (c) abrasion

Grinding can be done by several mechanisms, including impact or compression, due to forces applied almost normally to the particle surface; chipping due to oblique forces; and abrasion due to forces acting parallel to the surfaces. These mechanisms distort the particles and change their shape beyond certain limits determined by their degree of elasticity, which causes them to break. (Wills, 2006)

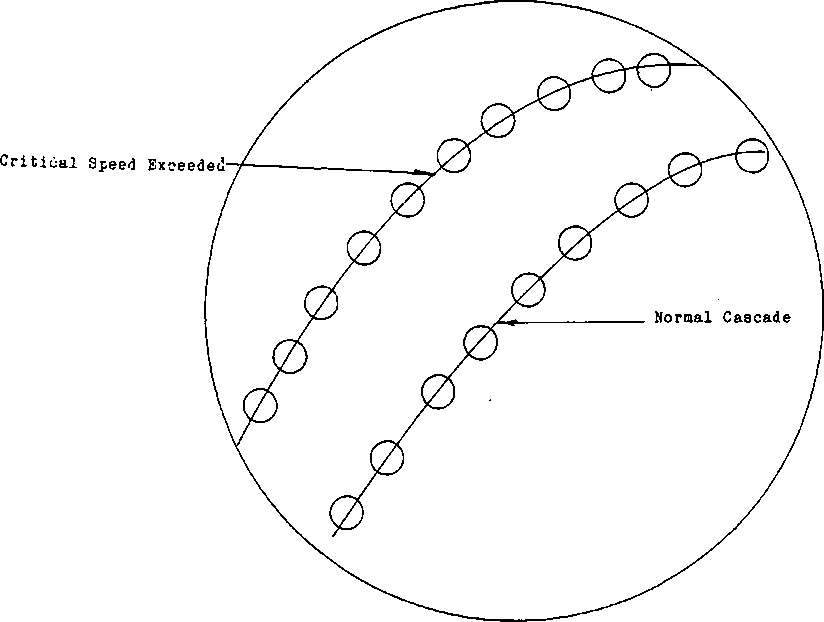

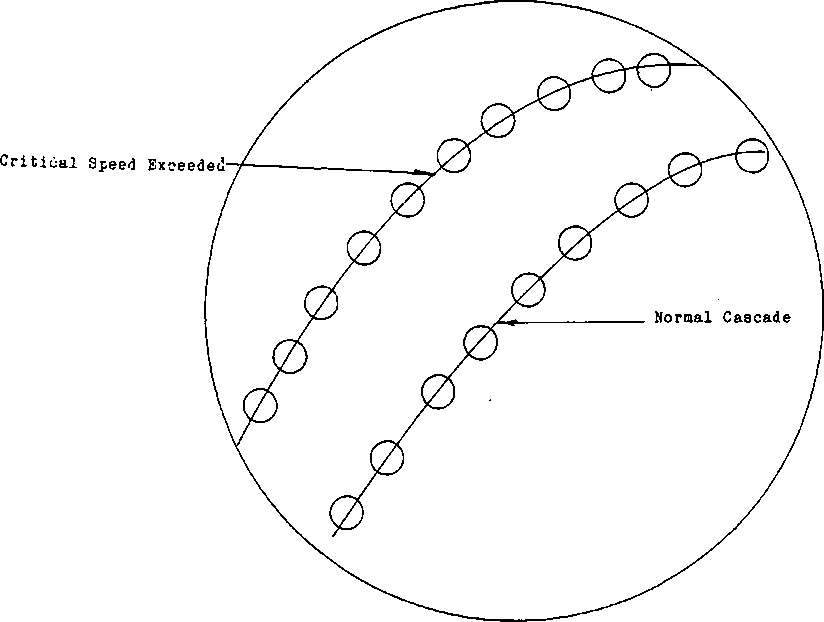

The motion in a grinding mill comprises two distinct varieties (Wills, 2006): Rotation of the rods or balls around their own axes lying parallel to the mill axis. CASCADING (rolling down the surface of the load) or CATARACTING (parabolic free fall above the mass).

Figure 2: Motion of charge in a tumbling mill (cascading and cataracting zones)

Mathematics of Grinding

Critical Speed: The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at the mill shell's inside surface. This is the rotational speed where balls will not fall away from the mill's shell.

Mills are driven, in practice, at speeds of 50-90% of critical speed, the choice being influenced by economic considerations. Increase in speed increases capacity, but there is little increase in efficiency (i.e. kWh/t) above about 40-50% of the critical speed.

Height attained: The maximum height up to which the particles go along the mill shell and then get thrown off and follow a parabolic path.

Power Consumption: As it earlier explained, grinding is the most energy-intensive operation in mineral processing. The basic formula for this is the Bond formula:

where P80 and F80 are the 80% passing sizes of product and feed in microns, and Wi is expressed as kWh/t.

The calculated power requirement is adjusted by utilizing efficiency factors dependent on the size of mill, size and type of media, type of grinding circuit, etc., to give the operating power requirement. (Rowland and Kjos, 1978)

Mechanical Construction

Mill shells: Mill shells are designed to sustain impact and heavy loading and are constructed from rolled mild steel plates welded together.

Mill ends: The mill ends or trunnion heads may be of nodular or grey cast iron for diameters less than about 1m.

Trunnions and bearings: The trunnions are made from cast iron or steel and are spigoted and bolted to the end plates, although in small mills they may be integral with the end plates.

Drive: Tumbling mills are most commonly rotated by a pinion meshing with a girth ring bolted to one end of the machine.

Mill feeders: The function of the feeder is to transport pulp from some receiving point outside the mill into the mill barrel smoothly... Three types of feeder are in use in wet-grinding mills:

- Spout feeder

- Drum feeder

- Combination drum-scoop feeder

Liners: Liners are the materials, which are used on the inner surface of the grinding shell to provide the necessary strength and resistance... Liner materials: Abrasion Resistant (AR) Steel, Ultra High Molecular Weight Polyethylene Plastics, Urethane liners (polyurethane elastomer), High Alumina Ceramic liners, Rubber liners, Metal magnetic liners etc.

Different types of mill liner plates (rubber lifters, shell liners, etc.)

Different Types of Mills

According to the ways by which motion is imparted to the charge, grinding mills are generally classified into three types: tumbling mills, stirred mills, and vibrating mills.

Figure 4: Different types of grinding mills (including SAG, ball, stirred, etc.)

Tumbling mills: In this mill, the mill shell is rotated and motion is imparted to the charge via the mill shell...

Figure 5: Mechanism of grinding in tumbling mills

Different Types of Tumbling Mills: Rod Mills, Ball Mills, Autogenous (AG) Mills, Semi-Autogenous (SAG) Mills...

Stirred mills: Tower mills (VertiMill), IsaMills (horizontal)...

Vibrating mills: High-energy vibration mills can grind materials to surface areas of around 500m²/g...

Cost of Grinding

The main costs for grinding are energy, liners and grinding media. They are different for different mill types.

Figure 6: Cost comparison of grinding in different mills

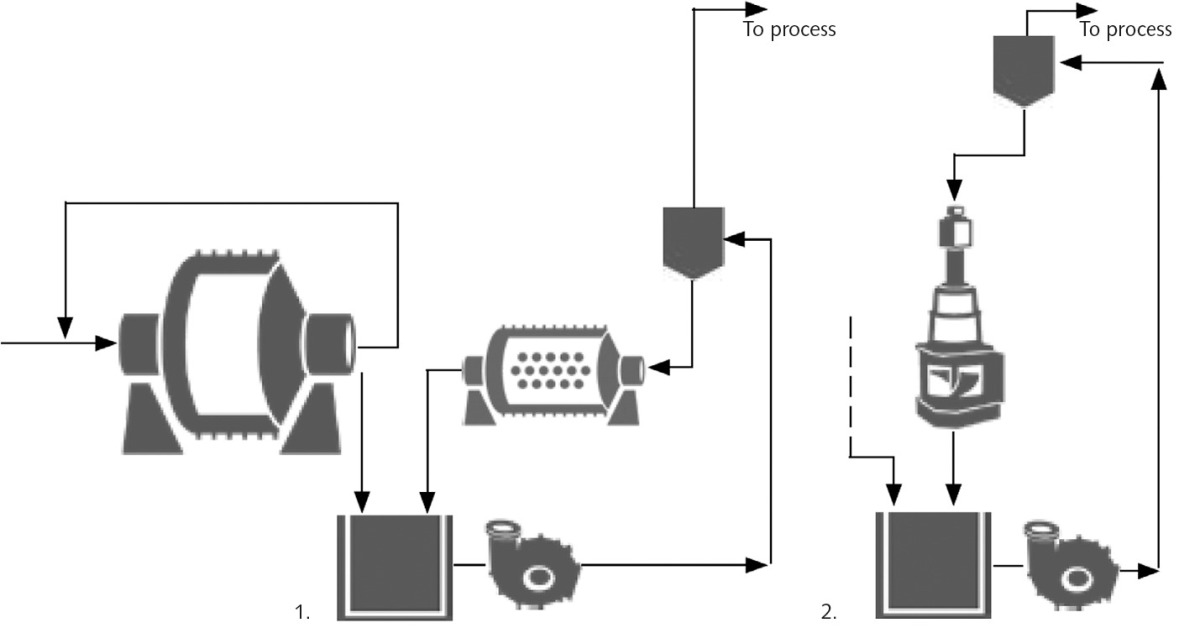

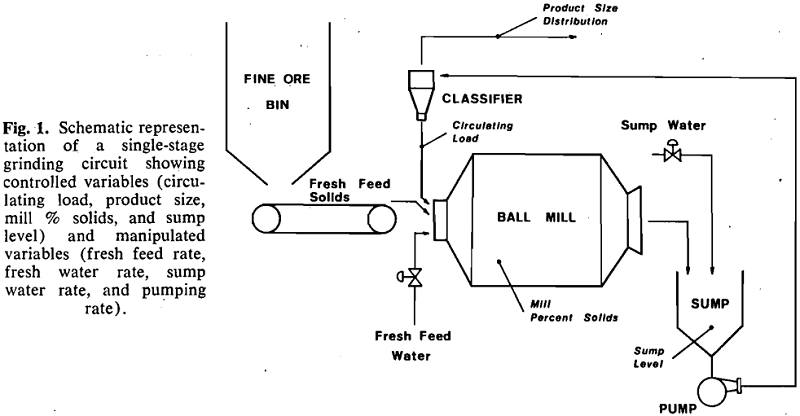

Grinding Circuits

The feed can be wet or dry, depending on the subsequent process and the nature of the product. Circuits are divided into two broad classifications: open and closed.

Figure 7: Single-stage closed circuit grinding example

Open vs Closed Circuit Grinding overview

Rod mills are generally operated in an open circuit... Ball mills are virtually always operated in a closed circuit with some form of classifier... In many recently designed plants, the traditional three stages crushing followed by rod and ball milling circuit has been replaced by the popular SABC circuit...

1 Comments

PHD

DBA

PHD Program

DBA Program

Honor Doctorate

Doctoral Degree

Honorary Doctor

Outstanding Chinese

International American University

Degree by Mill