Mining Engineering & Mineral Exploration Economics

Mining Engineering is a lot about applying the knowledge of applied science and Engineering Mechanics to the successful extraction of useful geological resources. So in this first module we will overview the mining process in its entirety and identify those aspects which are the realm of the mining engineering. Then in the next three modules we will look at the specifics of mining engineering in greater detail. We will devote this first topic to identifying the steps in the mining process, and to introducing the terminology that used in the mining industry and that will be used throughout this course.

The mining process begins with finding a new mineral deposit and it ends when the mine is abandoned after it has been rehabilitated. Basic steps in the mining process are:

- Mineral exploration to find a new deposit.

- Economic Assessment of the deposit to a prices viability mine design which we’ve a safe, stable and financially viable operation. This is the main job of the mining engineering.

- Environmental impact assessment mitigations

- Beneficiation of the mining product

- Handing on the mining products and wastes

- Mine closure in site remediation

These headings services as the list of topics we will cover

in this first module. Then in the three module that will follow we will see how

the mining engineering exploits geological deposits in a safe, efficient,

responsible and profitable way. So let’s start the first topic with the

introduction to the language of the mining engineering, but note that while we

have endevit to present this course using the terminology of the industry and

the profession, with terminology there is widely, locally, globally and from

commodity to commodity. With this reason we have included the glossary in the

additional resources, for you to refer to as required. Let’s start by defining

a mine.

- A Mine is an excavation made in the ground to recover minerals or ores.

- A Quarry is an excavation made in the ground to obtain soils and rock materials for civil construction.

- A Mineral is a naturally occurring inorganic geological substance with a defined chemical composition.

Strictly coal isn’t a mineral, because it’s organic in its

composition may vary. However, because it’s geologically derived, and because

it has a value it is usually considered to be an economic mineral, and in this

course we will consider it as such. Now let’s go on and define a deposit.

In defining a deposit we need to realise that there are

background traces of every element in our geologic materials so a mineral

Deposit is a natural geological occurrences of minerals in anomalously high

concentrations either as a body or disseminated.

An ore is a mineral that can be mined, and from which a

commodity of value can be extracted.

Gangue are minerals of no value that occur mixed with ore minerals.

To illustrate the ideas of ores and gangue let’s consider

these specimens. In this specimen we have a gold colored ore of copper called a

chalcopyrite associated with a black gangue Rock. In the second specimen we

have another ore of copper a green mineral called malachite in this case.

So let’s define some terms used to describe different types

of deposits .An ore body is a deposit of ore usually with gangue with

well-defined extent. Orebodies can be of any shape such as veins, layers,

lentils or pots. The Disseminated ore is the deposit where the ore is spread

throughout wet less rock without following the well-defined body.ore

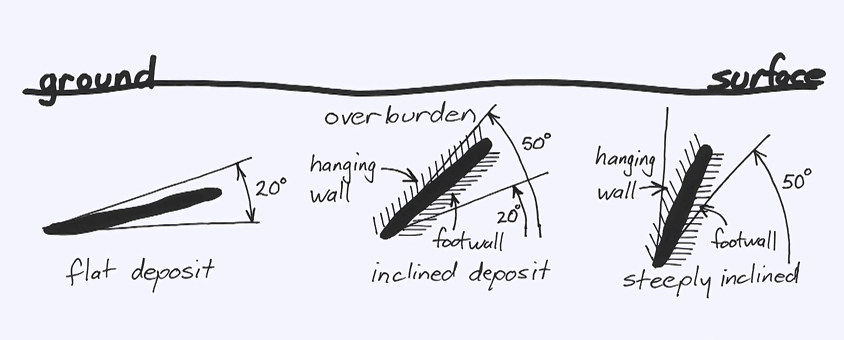

Overburden is the rock that lies directly above an ore body, if the body is not exposed directly at the surface. A Flat deposit is a mineral deposit occurring as a horizontal or gently dipping body, usually at an angle of less than about 20 degrees. An Incline deposit is a mineral deposit occurring as a dipping body, separated into inclined between 20 and 50 degrees and steeply inclined above about 50 degrees up to vertical. A Hanging Wall is the rock that forms the upper boundary of an inclined ore body, and the foot wall is the rock that forms the lower boundary of an inclined ore body.

The two ore bodies shown in the figure could be mined either by surface mining or by underground mining. Surface mine is a mine where the deposit is excavated directly at the ground surface or else have the bad grounds removed to expose the ore at the surface.

An underground mine is a mine that the deposit is work from

excavations from beneath the ground surface. Most is rock material that must be

removed with the minerals in order to recover them economically, but which has

no economic value. As you can see in the figure surface mines generally produce

more waste than underground mines.

Beneficiation is an industrial process carried out on a mined ore to increase its concentration and remove gangue.

Tailings is a term given to gangue and rock of no value,

that are separated from mined ore in a beneficiation process, and which usually

contain residues of the extracted ore minerals. In the next topics we will look

at the mining process in greater details, but in the meantime I encourage you

to visit the discussion forum and introduce yourself to the other students

taking this course.

Mineral Exploration

Before you can mine minerals you have to find them so it follows that the logical first step in the mineral process is mineral exploration. As minerals mostly occur in cells and rocks, it also follows that mineral exploration techniques draw heavily upon the science of geology. There are four basic approaches to mineral exploration these are:

- Geological Mapping

- Geochemical Exploration

- Geophysical Exploration

- Drilling geology

Whilst the distribution and structures of the geological

world may seem complex and strange the science of geology is built on patents.

A geological map is a representation of the geological structures and contour

below the surface. Through our experience and through our knowledge of science

we have learnt that certain type of mineral deposits always deplore in certain

geological settings. These are referred to as geological associations for

example we know that tin minerals are often found in pegmatite veins associated

with granites. Diamonds are often associated with geological deposits known as

kimberlites and Chromium minerals are often associated with ultramafic igneous

rocks. Hence if we can identify a particular geological setting it might lead

us to look for a particular types of mineral deposit. Geological mapping on a

large scale can identify geological settings of interest. To find mineral

deposits within these we can undertake refined mapping on a smaller scale, or

we can employ more specialized techniques such as geochemical exploration.

The earth’s crust is actually made of relatively few

different chemical elements. And so when samples of soils and rocks are

chemically analyzed they are typically dominated by silicon, oxygen, aluminum,

iron, sodium, potassium, calcium, magnesium and carbon with only traces of

these background levels of the more exotic elements that we obtain from

valuable ores. If samples are analyzed in anomalies high concentration with

pressures precious elements are found this couldn’t count the proximity of an ore

body. By specially correlating an anomalies concentrations and by following

trends of increase in concentrations we are led to find ore bodies.

Geophysics is the science of exploring the structure of the

earth, using waves energy of fields rather created, measured at the ground

surface. Geophysical exploration impose techniques based on geophysics. There

are many different geophysical principles, for example:

Ore bodies are relatively denser so the gravity above them

is enormously greater. Ore bodies are often metallic, so the electric or

resistivity of the ground that contains them is lower. Ore bodies have

different seismic velocity values, so they can change speed with which seismic

vibrations travel through them. And ore bodies often contain unusual amounts of

iron, so they produce anomalies in the local magnetic field.

Different geophysical methods can be used to define the

size, shape, position and composition of ore bodies beneath the surface.

Exploration drilling involves penetration the ground with a hole from which

samples can be collected. These are often collected in the form of continuous

sticks of rock. Drilling provides localized or quality information but it’s

expensive, and so it’s best to employ to define the expense in value of the

deposit, once it’s been discovered using broader scale techniques. So those are

the tools of exploration but how does the mineral exploration process actually

works.

To start mining companies employ exploration geologists to identify likely areas to search for mineral deposits. Initially these are identified from broad scale patents in the earth’s crust on the basis of geological associations. When a likely area identified the next stage is to employ geophysical techniques such as gravity surface or airborne magnetic surface to look for geological anomalies but could the ore bodies have scales of tens to hundreds of kilo meters. Where surface only surface possible are identified we might then undertake fill mapping or geochemical surveys or potentially we can look at geophysical maintenance of the morphidity near surface conditions, such as the use of ground penetrating radar. This could be carried out in scales of tens of kilometers. When deeper deposits are suspecting seismic and resistivity based geophysical methods can be used to define the size shape and likely extent of an ore body.

The presence of an ore body is

ultimately confirmed by drilling. Drilling in straight lines have various

inclinations to intercept a mineral deposit allows its size, shape position and

grade to be mapped in three dimensions. When these are known, mine design and

mine plan can be formulated, and then the economic viability of mining can be

assessed.

Is a Mineral Deposit Economic

Mineral deposits come in all sizes and shapes then engraves

from extremely rich to barely significant. So just because you find a mineral

deposit doesn’t mean you’re destined to become a morning Bengal. In this topic

we’ll consider the factors that determine the economic viability of the mineral

deposit. There are many factors which, in combination determine whether or not

exploitation of the mineral deposit is economically viable, these are:

- Size of Deposit that is the total extractable tons;

- the grade of the deposit (extent to which the ore is mixed with gangue a worthless mineral);

- the unit cost of winning the ore from the ground

- The unit cost of separating the ore from the waste rock and the gangue

- The unit cost of extracting the commodity from the ore during ice melting

- The cost of getting the ore commodity from the mine of the market.

- And the present worth of the commodity in the global market.

The total extractable tons of ore determines the gross worth

of the deposit all things being equal, larger deposits have greater potential

for generating greater returns. The economic viability of an ore deposit is

strongly influenced by the grade of the ore. It is generally not possible to

liberate an ore deposit without first even moving some quantity of worthless

rock and without some gangue being mixed with the ore. Usually in mining it is

not possible to separate the ore from the gangue, and this has to be done later

in an industrial process. Associated cost include;

- the cost of breaking, moving and storing the ore in waste rock, which are cost to equipment fuel and labor.

- And the cost of concentrating the ore, by separating it from the gangue.

There’s a cost of infrastructure establishment running cost

and waste disposal. Even after there’s concentrated the commodity of interest

seldom obtained directly. It usually has to be extracted from the concentrated

ore in a process generally known as smoking.

This can be more or less costly and difficult, depending on the

nature of the mineral, cots arise from;

- the cost of building refining cost at the mine or taking the concentrated ore to an existing place,

- operational costs which may be energy intensive and

- cost of pollution mitigation and waste disposal.

The primary consideration, the value of the commodity over

the life of the mine must exceed the cost of purchasing equipment, building

infrastructure, breaking and moving earth, refining ore and transporting

products.

By an amount representing good return on investment with the

anticipated market value of the commodity. Mining is undertaken to be a

profitable exercise.

In the secondary considerations it is necessary for the

mining operation remain profitable for most if not all phases of its design

life. And not just profitable from an overall consideration.

This is a challenge because most of the cost of moving

worthless ground, buying equipment, and building infrastructure is incurred

very early in the lie of the mine, and this is the time when the returns from

the product are very low. In planning a mine it must be possible to incur the

initial establishment cost and write those offset by acceptable financial

returns.

In some cases this can be achieved, by staging mine

development to occur gradually, over extended period as mining progresses in

other cases it might be possible to target an upper rich or high grade patented

ore body so that we maximize returns in the early stage of the mine, to offset

the cost of the establishment.

The economic viability of mineral deposits changes with

time, it is influenced by the market value of the commodity related to supply,

the cost of energy and technological innovation. Deposits though not

economically viable today may become economically viable in the future. This is

one reason why it is so difficult to estimate the global reserves of a given

mineral resource. As minerals become scarce and commodity process increase more

and more marginal mineral deposits become economically viable. So more economic

considerations specific to surface and underground mining will be considered

later.

Mining Engineer Tasks & Responsibility

In the topics covered so far we have mostly considered those

steps in the mining process leading up to the actual operation, and although

they are relevant in a broader context they don’t like the core of the mining

engineering principle. The arts of engineering has two principle aspects these

are:

- Achieving an outcome

- Doing so in an optimized way, subject to a complex array of limitations and constraints.

So with these all these in mind we can identify core tasks

of the mining engineering as being to produce a conceptual design that is:

Technically feasible; economically viable; environmentally responsible and most

importantly, fundamentally safe for miners. And to develop the conceptual

design to produce an operational plan which achieves the above aims at every

stage in the life of the mine. And to oversee the mining operation as it occurs

and continuously refine the plan with circumstances and conditions change and

problems arise. As with all engineering problems, there is no single unique way

to design a mine. There are probably as many different ways to mine a mineral

deposit as there are mining engineers. Solutions to this problem can generally

be grouped into two categories:

Those that simply won’t work, and not technically feasible; and those that will work but they may or may not be optimal. To develop a technically feasible mine design requires the application of the knowledge of science and engineering mechanics. One can envisage an amazing array of clever theoretical solutions to mine a mineral deposit. But assessment of the physical impracticality requires in every aspect of them be quantified in some way. There are many things to be decided but, they can generally be grouped in two categories:

- Will the geometric arrangement of the mine at any stage in its development be stable?

- And with the resources we have, (cable, tools, equipment, products) can we physically achieve that arrangement?

To answer these questions we need a quantified knowledge of applied science and engineering mechanics. specifically that knowledge should include; an understanding of stress and strain; fundamental behavior of rocks and discontinuities; stress distributions in the ground and mechanisms of instability and failure. We have devoted module two to a more detail consideration of some of these issues and the headings above serve as a list of the topics we will consider. Even after we have decided upon a physical arrangement or the mine and we have decided how that physical arrangement should evolve as the mine develops, we are not yet in a position to start mining. There are many different parts to achieve and outcome, there are many tools to use break rocks and excavate ores. There are many ways to transport rock and ore.

There are many option or managing waste, there are choices

to be made about how we balanced the development activities with production,

and how we want to run the mine as a business to optimize the return. Key

decisions that must be made include; should we use or surface or underground

mining methods? What methods would we use to break up the ore and waste rocks

to maximize effectiveness to minimize cost? What methods should we use to

transport the ore and waste rock? How much ore are we willing to sacrifice if

it allows us to use efficient excavation method? How do we manage mining and

beneficiation waste? What are our obligations regard to mine closure and

rehabilitation, and how do we manage safety? A large part of the role of the

mining engineer is to determine how mine operate, as their physical arrangement

evolves.

0 Comments