AI and Machine Learning in the Mobile Mining Industry

Advantages and Potential Implications for Mining’s Future

The mining sector has historically faced criticism for its environmental footprint and safety risks. However, the integration of artificial intelligence (AI) and machine learning (ML) is driving a profound transformation—making operations safer, more efficient, and significantly more sustainable.

AI-powered drones, sensors, and autonomous vehicles now perform high-risk tasks in remote areas, reducing human exposure to danger. Real-time data analytics and predictive capabilities help prevent accidents, optimize processes, minimize downtime, lower costs, and reduce environmental impact.

This article explores 5 key applications of AI/ML in the mining industry (with emphasis on mobile and operational technologies), their advantages, and what the future may hold.

1. Enhancing Miner Safety

The mining industry has achieved remarkable safety improvements, and AI is accelerating this trend through predictive analytics and real-time monitoring.

Wearable AI tools, such as fatigue-detection helmets like SmartCaps (deployed by BHP in Chilean copper mines), monitor brainwaves to detect drowsiness or fatigue in equipment operators and issue immediate alerts.

.jpg)

Operator using SmartCap fatigue management technology (Source: Wenco / SmartCap)

Machine learning analyzes equipment sensor data to predict mechanical failures, averting catastrophic incidents, cutting repair expenses, and eliminating operator risk.

Technologies like Rockmass Technologies integrate AI with LiDAR for fast, detailed geotechnical mapping of underground tunnels—automatically generating critical metrics (stereonets, Q-System, RMR) to enable rapid ground support decisions.

2. Autonomous Vehicles & Equipment

One of the most impactful AI applications in mining is the deployment of autonomous haul trucks, loaders, drill rigs, and drones that operate safely in hazardous and remote environments without human operators.

These systems navigate difficult terrain, avoid obstacles, and perform drilling, blasting, hauling, and loading—substantially increasing productivity while removing personnel from danger zones.

Drone conducting aerial survey and monitoring in a mining site

Drone-enabled inventory and site management in mining

Autonomous equipment continues operating during shift changes and blasting periods—especially valuable in underground mines where travel time creates lengthy downtime. Mines slow to adopt this technology risk losing their competitive edge in cost and efficiency.

3. Revolutionizing Mining Exploration Efficiency

AI and ML dramatically improve the speed and accuracy of mineral exploration by analyzing geospatial, satellite, and historical data to identify high-probability deposit locations—reducing expensive and time-intensive fieldwork.

Advanced machine learning image processing instantly identifies lithologies in drill core photos, face images, and pit walls—accelerating data collection critical for mine planning.

KoBold Metals' AI-powered predictive exploration system integrating sensors, data, and models

KoBold Minerals exemplifies this approach—using sophisticated AI models combining satellite and traditional datasets to target critical battery metals. The company is advancing dozens of global projects and forming joint ventures with major miners.

4. Predictive Maintenance

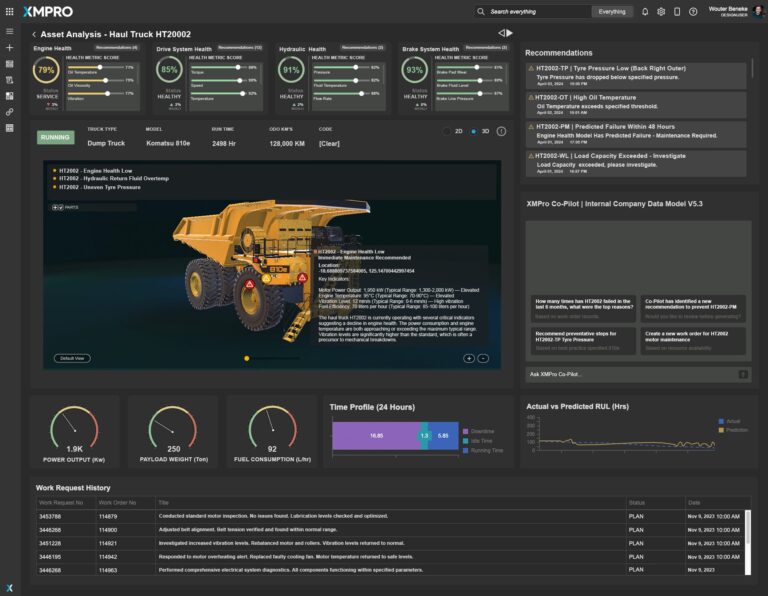

In the mobile mining fleet, AI/ML-driven predictive maintenance systems analyze real-time sensor data from haul trucks, loaders, and other equipment to forecast when maintenance is needed—drastically reducing unplanned downtime and boosting productivity.

AI dashboard monitoring haul truck asset health and predicting failures (Source: XMPRO)

IoT-based predictive analytics dashboard for mining fleet performance

Algorithms identify failure patterns and root causes, enabling proactive interventions that cut costs, prevent accidents, and optimize overall operations.

5. Minimizing Environmental Impact

Mining can cause erosion, biodiversity loss, soil contamination, and other environmental harm—but AI is helping mitigate these effects through continuous, intelligent monitoring.

Sensors and cameras detect anomalies (temperature changes, vibrations, chemical leaks) to prevent incidents and disasters. AI optimizes ventilation systems to save energy and reduce waste.

Tailings storage facility—critical site for AI-enabled real-time stability monitoring

Continuous AI analysis of tailings dam sensor data enables early detection of structural weaknesses, preventing catastrophic failures and supporting more sustainable practices across the industry.

What Does the Future of Mining Look Like?

AI adoption in mining is accelerating rapidly. The global AI in mining market, already substantial, is projected to grow dramatically in the coming years.

Future advancements will likely include more sophisticated AI equipment, enhanced predictive accuracy, virtual reality simulations for training and testing, and ultra-fast real-time decision-making enabled by 5G connectivity.

Exploration success rates—historically very low—could improve significantly, helping secure future supplies of critical minerals needed for clean energy technologies.

However, responsible adoption is essential. Potential job displacement requires thoughtful retraining programs, while robust data security measures must protect sensitive information.

Through industry collaboration on ethical guidelines and best practices, AI can help create a mining sector that is safer, more efficient, environmentally responsible, and beneficial for communities and the planet.

The mines that embrace AI today will define the safer, greener, and more productive mining industry of tomorrow.

0 Comments