How to Calculate Core Recovery and RQD of Rock?

Essential parameters for assessing rock mass quality in mining, tunneling, and geotechnical engineering – with practical examples and visuals

Typical rock core samples from diamond drilling – key for recovery assessment

Introduction to Core Recovery and RQD

In mining geology, geotechnical engineering, and civil projects (tunnels, dams, foundations), diamond core drilling provides critical subsurface data. Two fundamental indices derived from recovered cores are:

- Core Recovery (CR): Simple percentage of material retrieved vs. drilled length.

- Rock Quality Designation (RQD): A more refined index introduced by Deere in 1963, focusing on sound, intact pieces longer than 100 mm to evaluate rock mass quality.

These parameters help classify rock mass, predict stability, select support systems, estimate excavation behavior, and guide blasting design.

Drill core boxes ready for logging – showing varied recovery and fracturing in real samples

Core Recovery (CR) Calculation

Core recovery is the easiest and most basic measure of drilling success and rock competence.

Formula:

CR (%) = (Total length of recovered rock / Total core run length) × 100

All recovered pieces are included, regardless of size or condition (even fragments from drilling breaks). High CR (>90%) indicates good drilling technique and relatively competent rock; low CR suggests friable, fractured, or weathered zones.

Detailed step-by-step illustration of core recovery and RQD calculation on a 1.2 m run (CR = 96% in this example)

Rock Quality Designation (RQD) Calculation

RQD modifies core recovery by considering only sound (hard, unweathered) core pieces ≥ 100 mm long, measured along the centerline.

Formula:

RQD (%) = (Sum of lengths of sound core pieces > 100 mm / Total core run length) × 100

Key rules:

- Only sound rock counts — exclude highly weathered, altered, or discolored pieces even if >100 mm.

- Measure along centerline (not arc length).

- Fit together pieces broken by drilling (fresh, rough surfaces) and count as one piece.

- For natural fractures: separate pieces unless clearly drilling-induced.

Close-up of core logging – measuring and classifying pieces for accurate RQD

Step-by-Step Example (from Illustration)

Consider a 1200 mm core run with these piece lengths (along centerline):

- 250 mm (sound)

- 200 mm (highly weathered → exclude from RQD)

- 250 mm (sound)

- 190 mm (sound)

- 60 mm (exclude)

- 80 mm (exclude)

- 120 mm (sound)

- 0 mm (no recovery)

Core Recovery: 1150 mm recovered → CR = 96%

RQD: Sound pieces >100 mm = 810 mm (or adjusted per diagram: \~53% in example)

Annotated core box showing fractured intervals and numbering for logging – typical in mining projects

Rock Quality Description Based on RQD

| RQD Value | Description of Rock Quality |

|---|---|

| 0–25% | Very poor |

| 25–50% | Poor |

| 50–75% | Fair |

| 75–90% | Good |

| 90–100% | Excellent |

This classification (Deere & Miller) is widely used in rock mass rating systems like RMR and Q-system.

Important Notes and Best Practices

- RQD is best with NX or NQ core sizes (optimal); avoid BQ/BX due to smaller diameter.

- Drilling-induced breaks (fresh, rough surfaces) should be fitted and counted as one piece.

- In laminated or thinly bedded rocks, distinguish natural vs. induced fractures conservatively.

- For shear strength: exclude near-horizontal breaks (conservative); for blasting: include them (conservative).

- Log cores immediately after recovery; photograph core boxes; note orientation marks.

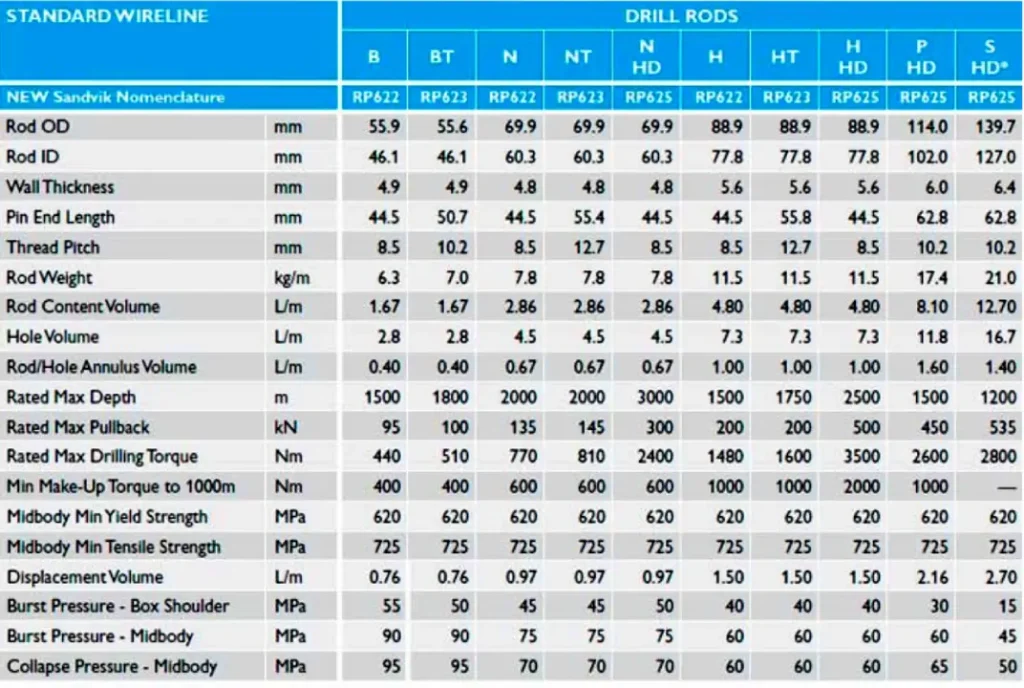

Wireline double-tube core barrels (BQ, NQ, HQ, PQ) – NQ is preferred for reliable RQD assessment

Standard wireline core sizes comparison chart (BQ, NQ, HQ, PQ) – crucial for choosing appropriate drilling tools

Applications in Mining and Geotechnical Projects

In Indian mining contexts (coal in Nagpur/Maharashtra, iron ore in Odisha, etc.):

- Low RQD zones indicate need for roof bolting, shotcrete, or reduced panel widths in underground coal mines.

- High RQD (>75%) supports wider spans and higher extraction ratios.

- RQD helps in slope stability analysis for open pits and waste dumps.

- Used in tunnel support design (e.g., NATM classification).

Another view of core logging setup – highlighting fractured vs. intact zones

Conclusion

Core Recovery gives a quick snapshot of material return, while RQD provides a robust indicator of rock mass integrity by discounting weathered and short pieces. Accurate measurement during core logging is crucial for reliable geotechnical models, safe mine design, and cost-effective operations. Always follow ISRM or ASTM standards for consistency.

Mastering these calculations enhances rock mass classification and supports better decision-making in exploration and extraction.

Have questions about core logging or RQD in your project? Drop a comment below!

0 Comments