Volvo I-Shift vs Competitors: Ultimate Mining Transmission Guide 2025–2026

In the high-stakes world of mining operations, where haul trucks and articulated dumpers face extreme loads, steep grades, and non-stop cycles, the right mining transmission directly impacts fuel costs, uptime, and operator safety. The Volvo I-Shift automated manual transmission (AMT) remains a benchmark for intelligent shifting, especially with its latest severe-duty and crawler gear enhancements. But how does it truly compare to leading competitors like Allison fully automatics, Eaton UltraShift, and ZF TraXon in 2025–2026 mining applications?

This comprehensive guide breaks down technical specs, real-world performance in open-pit and underground mining, efficiency calculations, common pitfalls, and actionable improvement tips—helping fleet managers, mining engineers, and operators worldwide make data-driven decisions.

Why Transmission Choice Matters in Modern Mining Operations

Mining transmissions must endure torque loads exceeding 2,500 Nm, frequent start-stop cycles, dust, vibration, and temperature extremes. In major mining regions—Australia’s Pilbara iron ore, Chile’s copper belt, Canada’s oil sands, and India’s coal fields—a suboptimal transmission can inflate fuel consumption by 5–10%, increase maintenance downtime, and elevate safety risks from rollaways or harsh shifts.

Modern AMTs like the Volvo I-Shift use predictive algorithms (road grade, load, GPS data via I-See) to optimize shifts, delivering 3–7% better fuel economy than traditional manuals and competing automatics in variable mining conditions. Fully automatics (e.g., Allison) excel in seamless power delivery for frequent stops, while other AMTs offer modularity and torque capacity.

Technical Breakdown: Volvo I-Shift vs Key Competitors (2025–2026 Specs)

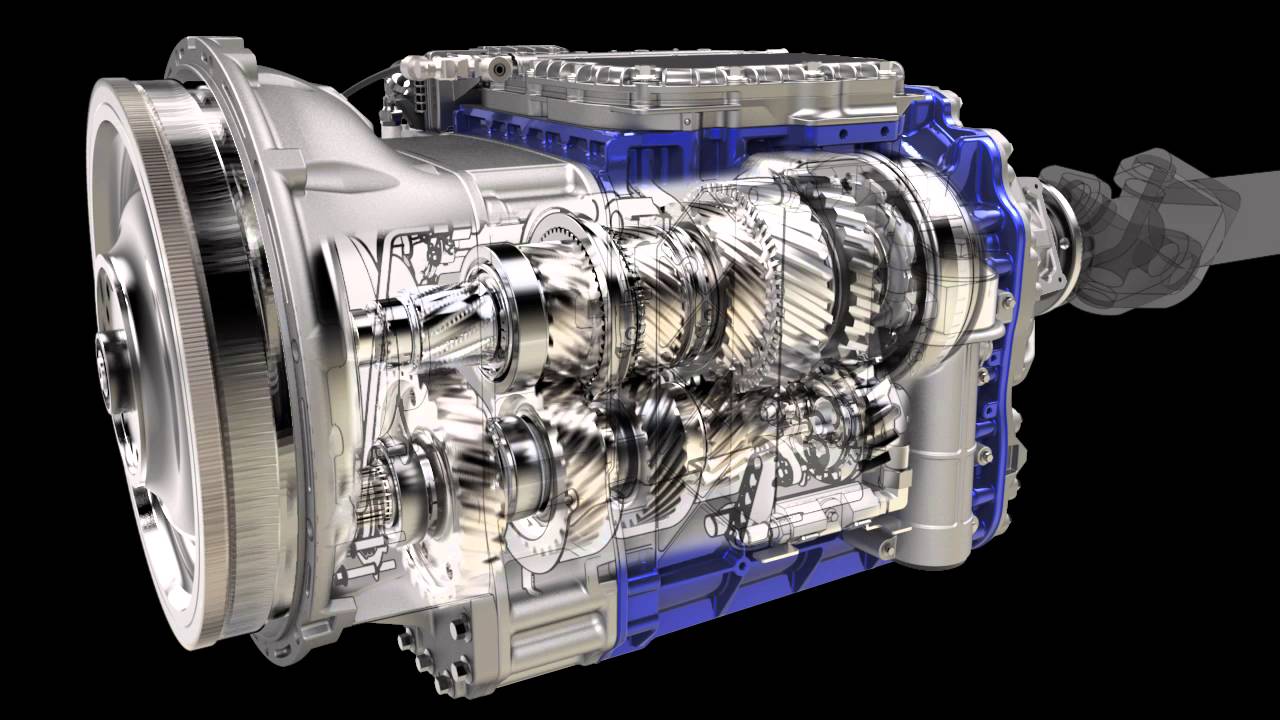

The latest Volvo I-Shift (Severe Duty + Crawler Gears variants) features:

- 12–14 forward gears + up to 6 reverse

- Max torque: up to 2,600 Nm (AT2612 series)

- Crawler gear ratios: low crawler \~19.38:1, ultra-low crawler \~32.04:1 (14-speed version; overall ratio up to 41.08:1)

- Weight: 278–324 kg (crawler version heavier due to extension unit)

- Oil capacity: 16–18.6 L (high-capacity cooler)

- Key features: I-See predictive shifting, Terrain Brake, Heavy Start Engagement, Performance Shift mode, Auto Neutral

Competitor Comparison Table

| Transmission | Type | Max Torque | Speeds (Fwd) | Key Mining Strength | Fuel Efficiency Edge |

|---|---|---|---|---|---|

| Volvo I-Shift (Severe Duty + Crawler) | AMT | 2,600 Nm | 12–14 | Ultra-low crawler for 325 t GCW, predictive shifting | Best in variable grades (3–7% savings) |

| Allison (e.g., 9000/9610 Series) | Full Automatic | \~3,000+ Nm | 6–7 | Torque converter—no clutch wear, smooth in stop-go | Lower in continuous haul (hydraulic losses) |

| Eaton UltraShift PLUS HD | AMT | \~2,800 Nm | Up to 18 | Deep reductions, Hill Start Aid | Competitive, slightly slower shifts |

| ZF TraXon | AMT | Up to 3,200 Nm | 12–16 | High modularity, excellent for extreme torque | Very close to I-Shift |

Efficiency Calculation: How to Compare Mining Transmissions

Transmission efficiency (η) = (Output Power / Input Power) × 100%

Power (kW) = (Torque [Nm] × RPM × 2π) / 60,000

Step-by-Step Example – Volvo I-Shift in Haul Cycle

- Input: 2,500 Nm @ 1,300 RPM → Input Power ≈ 340 kW

- Top gear ratio 0.78:1 → Output speed ≈ 1,667 RPM, torque ≈ 1,950 Nm

- Theoretical output power ≈ 340 kW (no losses)

- Real losses: \~2% per mesh (assume 4–5 meshes + auxiliaries) → \~8–10% total loss

- Actual output ≈ 306–312 kW → Efficiency ≈ 90–92% (I-Shift often reaches 94–96% optimized)

- Allison torque converter: additional 5–10% loss at lock-up → \~85–90%

In mining, a 4% efficiency gain translates to thousands of liters of diesel saved annually per truck.

Real-World Mining Examples: Open-Cast & Underground

Open-Cast Example (India – Coal / Iron Ore): Volvo FMX or A60H articulated haulers with I-Shift crawler gears handle 50–60 t payloads on 12–15% grades. The ultra-low crawler (32:1) allows controlled 0.5–1 km/h creeping for precise dumping—reducing brake wear and tire slip. Fleet reports show 4–6% fuel savings vs Eaton-equipped units in similar duty cycles.

.jpg)

Common Mistakes When Specifying Mining Transmissions

- Choosing full automatic for long-haul grades → higher fuel burn

- Ignoring crawler/low gears for steep starts → clutch overheating or stall

- Skipping severe-duty hardening → premature gear wear

- Using wrong oil spec (e.g., not Volvo 97318 ultra-long drain) → reduced intervals

- No driver training on I-See / Performance modes → lost efficiency

Performance & Safety Optimization Tips for Mining Fleets

- Use high-capacity oil cooler + Volvo-approved 97318 synthetic fluid for 800,000+ km drains

- Activate Heavy Start & Terrain Brake for soft ground or steep inclines

- Train operators on one-pedal driving and Auto Neutral to prevent rollaways

- Monitor gearbox temp via dash display; intervene early on overheating

- Leverage telematics to benchmark I-Shift fuel use vs competitors quarterly

FAQ: Volvo I-Shift Mining Transmission Questions Answered

What makes Volvo I-Shift crawler gears ideal for mining?

Ultra-low ratios (up to 32:1 + 41:1 overall) enable starts with 325 t GCW and precise low-speed control—perfect for heavy haul and dumping.

Is Allison better than I-Shift for underground mining trucks?

Allison offers clutch-free durability in constant stop-go; I-Shift provides better fuel economy and integration with Volvo powertrains.

What is the latest max torque for Volvo I-Shift in 2025–2026?

Up to 2,600 Nm on AT2612 series, suitable for most mining ADTs and rigid haulers.

How does I-Shift compare to ZF TraXon or Eaton in torque capacity?

ZF leads at 3,200 Nm; Eaton \~2,800 Nm; I-Shift at 2,600 Nm but wins on predictive intelligence and crawler versatility.

Can I calculate fuel savings from switching to I-Shift?

Yes—use efficiency formula above + real load/grade data; expect 3–7% savings in mixed mining cycles.

Conclusion: Choosing the Best Mining Transmission in 2025–2026

The Volvo I-Shift—especially with crawler gears, I-See, and severe-duty upgrades—remains a top performer for intelligent, fuel-efficient mining haulage worldwide. While Allison dominates in pure stop-go reliability and ZF/Eaton offer higher torque ceilings, the I-Shift’s blend of efficiency, low-speed control, and Volvo ecosystem integration often delivers the lowest total cost of ownership. Evaluate your specific grades, payloads, and duty cycles, then spec accordingly—your next fleet decision could save millions in fuel and maintenance.

0 Comments